• Air condensation

• Evaporator of insulated tank immersion type or multi-tubular type

• Complete hydraulic circuit: tank, pump, manometer, etc.

• Coolant: R410A

• Free-cooling on request

• Heat recovery

![]() Ice water unit designed for machine and process chilling. The device is loaded with coolant (R410A) and subjected to complete operational tests in the factory. Numerous optional extras: Stainless steel tank, 5 bar tank, anti-freeze resistance, desuperheater, etc.

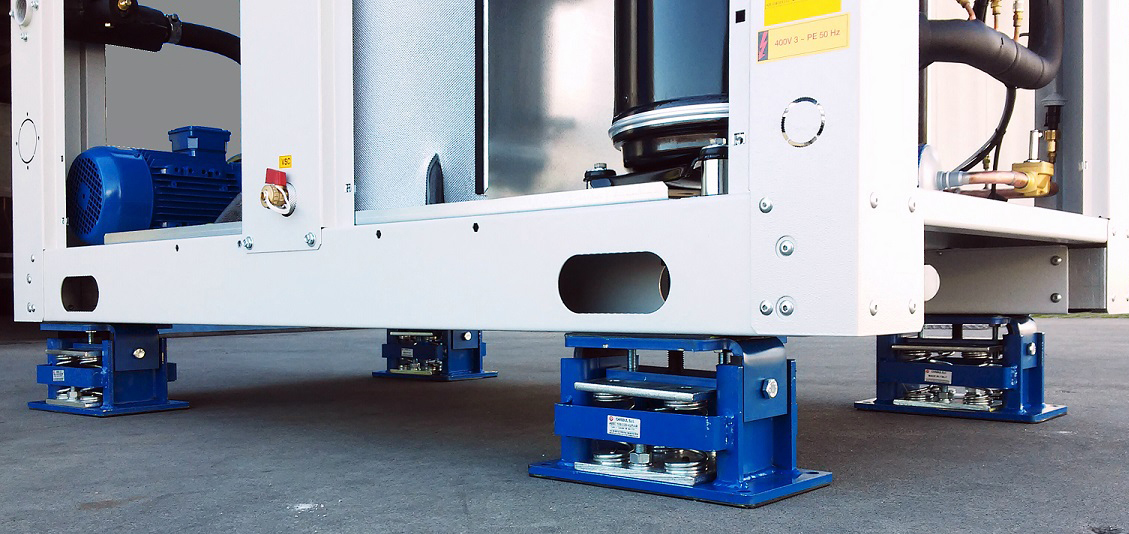

Ice water unit designed for machine and process chilling. The device is loaded with coolant (R410A) and subjected to complete operational tests in the factory. Numerous optional extras: Stainless steel tank, 5 bar tank, anti-freeze resistance, desuperheater, etc.

– Frame: Made with electro-welded extra-thick steel tubes

– Panels: Painted steel RAL7035

– Compressor(s): Rotating (ENR 005) or scroll type (ENR 008 to ENR 480)

Evaporator(s):

Soldered stainless steel plate type (for ENR001/002)

Insulated buffer tank immersion type (ENR.003 to ENR100)

Multi-tubular type (ENR130 to 480)

– Air condenser: Battery of copper tubes and aluminium fins

– Fan(s): Helical, speed variation type (as of ENR 030)

Refrigeration circuit:

The refrigeration circuits are produced (according to model) with mono, bi or tri-compressor in

tandem configuration.

2 refrigeration circuits for 130 to 440 kW models

Main components:

Expansion capillary (according to model)

Thermostatic pressure-reducing valve (according to model)

Dehydrating filter

Liquid indicator (according to model)

Liquid solenoid valve (according to model)

HP/BP safety pressure switch(es) (according to model and optional extra)

HP/BP manometer(s) (according to models and optional extra)

Complete hydraulic circuit:

Carbon steel buffer volume (Fe 360)

2.5 bar pump

Enables operational inertia

Pressure-relief valve for pressurised circuit (according to model)

Water manometer (according to model)

Flow controller for evaporator protection (according to model)

Manual air vent valve (according to model)

By-pass (optional extra)

Regulation:

Basic electronic regulator with digital display (according to model and optional extra)

Microprocessor with digital display (according to model and optional extra)